Maintaining Quality in CNC Machining: Best Practices for Adept Results

CNC machining stands as a cornerstone in modern manufacturing, offering precision, efficiency, and versatility. However, the true prowess of CNC machining lies not just in the technology itself but in maintaining stringent quality standards. At Adept Corporation, we recognize that quality is paramount. This article will delve into the best practices for ensuring top-tier quality in CNC machining, ensuring that products meet and exceed both industry standards and customer expectations.

Understanding CNC Machining Quality

Quality in CNC machining translates to the accuracy, surface finish, and dimensional integrity of the machined parts. It involves a holistic approach, encompassing material selection, machine setup, tooling, programming, and inspection. High-quality CNC machining minimizes waste, reduces rework, and ensures that each part functions as intended in its final application.

Best Practices for Maintaining Quality

- Material Selection: Choosing the right material is critical. It should suit the part’s application, machining processes, and desired properties such as strength, durability, and corrosion resistance. At Adept, we use premium materials and verify their quality upon receipt to prevent issues during machining.

- Proper Machine Setup and Maintenance: Regular maintenance of CNC machines ensures their optimal performance and accuracy. Calibration, cleaning, and routine checks help prevent mechanical inaccuracies that can lead to defects in the final product.

- Tooling and Equipment: Using the right tools for each job and ensuring they are in good condition is crucial. Dull or inappropriate tooling can affect the precision and finish of the machined parts. Adept Corporation invests in high-quality tooling and conducts regular inspections to maintain sharpness and efficiency.

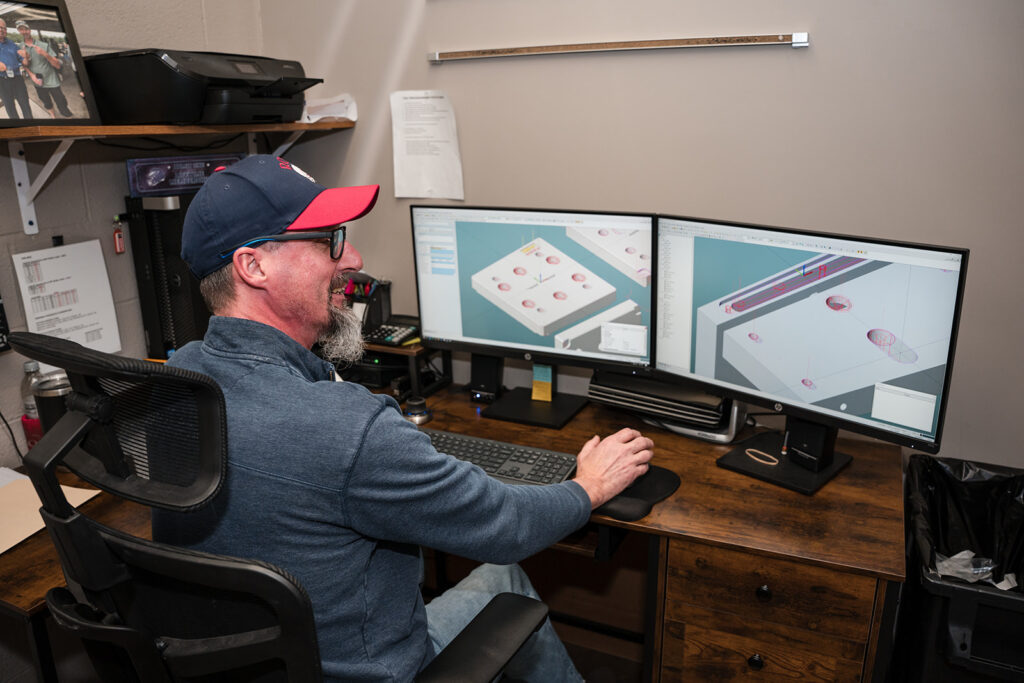

- Skilled Programming: The expertise of the CNC programmer significantly impacts the quality of the final product. Efficient and accurate programming minimizes errors and maximizes the potential of the CNC machine. Adept’s CNC programmers are highly skilled and experienced, ensuring that each program is optimized for the best possible outcome.

- Precision in Setup and Fixturing: Proper setup and fixturing of the material in the CNC machine are vital to prevent movement during machining, which can lead to inaccuracies. Adept uses precise jigs and fixtures to hold materials securely, ensuring consistent and accurate machining.

- Comprehensive Quality Control Processes: Implementing a robust quality control (QC) process is non-negotiable. This includes pre-machining checks, in-process inspections, and post-machining assessments. Adept Corporation employs a comprehensive QC strategy, utilizing state-of-the-art measuring tools and equipment to verify dimensions, surface finishes, and other critical specifications.

- Continuous Training and Education: The CNC machining landscape is continually evolving. Ongoing training and education ensure that our team stays abreast of the latest techniques, technologies, and quality standards. At Adept, we invest in our people, empowering them with the knowledge and skills needed to deliver exceptional quality consistently.

- Leveraging Advanced Technologies: Incorporating advanced technologies like 3D scanning and CAD/CAM software improves precision and reduces errors in CNC machining. Adept leverages these technologies to enhance our machining processes and output quality.

- Customer Collaboration and Communication: Open communication with customers ensures that all specifications and requirements are understood and met. At Adept, we collaborate closely with our clients, providing regular updates and seeking feedback to ensure the final product meets their exact needs.

- Fostering a Culture of Quality: Perhaps most importantly, maintaining high-quality CNC machining requires a culture that prioritizes and values quality at every level of the organization. At Adept Corporation, quality is at the heart of everything we do, from the shop floor to the executive suite.

Challenges in Maintaining Quality

Maintaining quality in CNC machining can be challenging, given the complexity of the processes and the precision required. Material inconsistencies, machine wear and tear, human error, and programming complexities can all impact quality. Overcoming these challenges requires vigilance, dedication, and a systematic approach to quality management.

Continuous Improvement in Quality

At Adept Corporation, we view quality as a continuous journey, not a destination. We employ continuous improvement methodologies, such as Six Sigma and Lean Manufacturing, to analyze our processes, identify areas for improvement, and implement strategic changes. This proactive approach allows us to stay ahead of quality issues and continuously elevate our standards.

Conclusion: The Adept Commitment to Quality

In the competitive landscape of CNC machining, maintaining superior quality is not merely an advantage—it’s a necessity. At Adept Corporation, our commitment to quality permeates every aspect of our operations. By adhering to best practices, leveraging the latest technologies, and fostering a culture that values excellence, we ensure that our CNC machining services meet the highest standards.

The path to maintaining quality in CNC machining is ongoing and ever-evolving. As we continue to embrace new challenges and opportunities, our dedication to quality remains unwavering. By prioritizing precision, efficiency, and customer satisfaction, Adept Corporation stands as a beacon of excellence in the CNC machining industry.