Material Choices in Metal Stamping: Finding the Right Fit

In the intricate world of metal stamping, the choice of material is not just a matter of selection but a foundational decision that impacts every aspect of production and the final product’s performance. At Adept Corporation, understanding and navigating the complexities of material selection is a cornerstone of our operation, ensuring we meet and exceed industry standards and client expectations.

Understanding Metal Stamping Materials

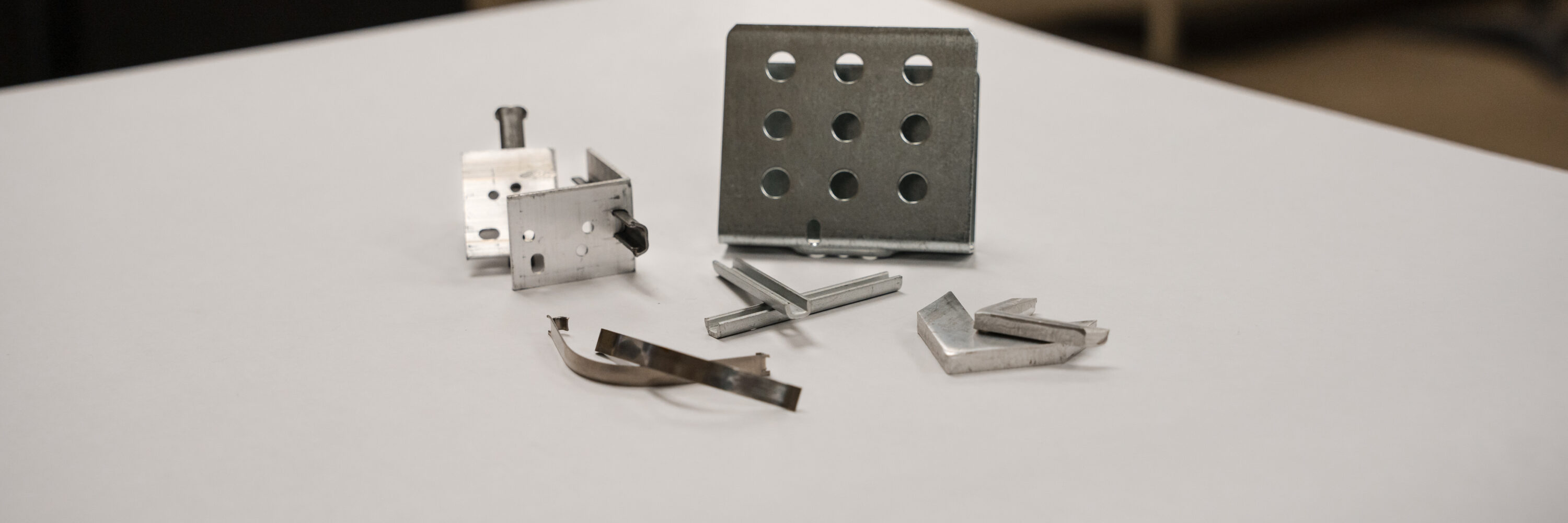

Metal stamping transforms flat metal sheets into precise shapes and designs through a high-pressure process. The choice of material affects the stamping process’s efficiency, the product’s quality, durability, and cost-effectiveness. Here’s a look at some commonly used materials in metal stamping and their distinct properties:

- Steel and Stainless Steel: Known for their strength and durability, these materials are widely used in automotive, construction, and appliance industries. Stainless steel, with its corrosion resistance, is particularly favored in medical and food processing applications.

- Aluminum: Lightweight yet strong, aluminum is preferred for its corrosion resistance and conductivity. It’s commonly used in automotive, aerospace, and consumer electronics.

- Copper and Brass: These materials are known for their electrical conductivity, making them ideal for electrical components. Brass, an alloy of copper and zinc, is also noted for its corrosion resistance and is commonly used in plumbing and decorative applications.

- Specialty Alloys: These include materials like Inconel, Monel, and Hastelloy, known for their ability to withstand extreme environments. They are typically used in aerospace, chemical processing, and marine applications.

Choosing the Right Material for Your Project

Selecting the appropriate material for a metal stamping project involves considering several factors:

- Application Requirements: The final product’s environment and use play a significant role in material selection. For example, parts exposed to harsh chemicals or high temperatures may require specialty alloys.

- Material Properties: Strength, malleability, conductivity, and corrosion resistance are just a few properties that dictate how a material will perform under stamping processes and in its final application.

- Cost Efficiency: Budget constraints can significantly influence material choice. While certain alloys may offer superior properties, alternatives might provide a more cost-effective solution without compromising quality.

- Availability and Sustainability: Material availability can affect lead times and overall project timelines. Additionally, sustainability concerns are leading more companies, including Adept, to consider recycled materials to minimize environmental impact.

Adept Corporation’s Approach to Material Selection

At Adept Corporation, material selection is a collaborative process that involves our engineers, clients, and suppliers. Here’s how we ensure the best material choice for every project:

- Comprehensive Consultation: We start by understanding the client’s needs, application requirements, and budget constraints. This holistic approach ensures that we select materials that align with the project’s goals and specifications.

- Expertise and Experience: With years of experience in metal stamping, our team has developed a deep understanding of how different materials behave under various conditions. This expertise allows us to recommend the most suitable materials for any given application.

- Testing and Prototyping: We employ rigorous testing and prototyping phases to evaluate how different materials respond to stamping processes and how they perform in real-world applications.

- Sustainability Practices: In line with our commitment to sustainability, Adept Corporation incorporates recycled materials into our projects whenever possible. This approach not only reduces environmental impact but also can offer cost benefits to our clients.

- Quality Assurance: Regardless of the material chosen, our comprehensive quality assurance process ensures that every stamped part meets our high standards of quality and reliability.

The Impact of Material Choice on Metal Stamping

The selection of material directly impacts the stamping process’s efficiency and the quality of the finished product. For instance, softer metals like aluminum may require different tooling and handling compared to harder metals like stainless steel. The material’s thickness, grain direction, and surface finish can also affect the tooling design, stamping force required, and the need for additional finishing processes.

Furthermore, the chosen material can influence the overall cost of the project. More expensive materials or those requiring specialized processing can increase production costs. However, the right material choice can lead to improved product performance, longer lifespan, and higher customer satisfaction, ultimately offering better value.

Conclusion: Material Matters

In metal stamping, as in all manufacturing processes, the right material choice is paramount. At Adept Corporation, we don’t just select a material; we choose a path to success for each project, considering all variables to ensure the final product meets all functional, aesthetic, and budgetary requirements.

As the industry evolves, so too do the materials and technologies at our disposal. By staying at the forefront of these changes and maintaining our commitment to quality and sustainability, Adept Corporation continues to be a leader in the metal stamping industry. Through our careful material selection process, we ensure that every product we stamp is not only built to last but also built responsibly.