Plastic extrusion, a cornerstone of modern manufacturing, is a process Adept Corporation has honed to perfection since our inception in 1966. This high-volume manufacturing technique transforms granular plastic into a continuous, profiled shape, offering solutions for a myriad of applications, particularly in the building industry. But what exactly is plastic extrusion, and how does it fuel the innovations at Adept Corporation? Let’s delve into the intricacies of this process and unveil its significance in today’s industrial landscape.

The Essence of Plastic Extrusion

At its core, plastic extrusion is about melting and molding. We start with raw plastic materials, typically in the form of small granules or pellets, and guide them through a complex journey of heating, shaping, and cooling. This journey begins in the hopper, where the plastic starts its transformation, moving to the feedthroat and then into the heart of the process – the barrel.

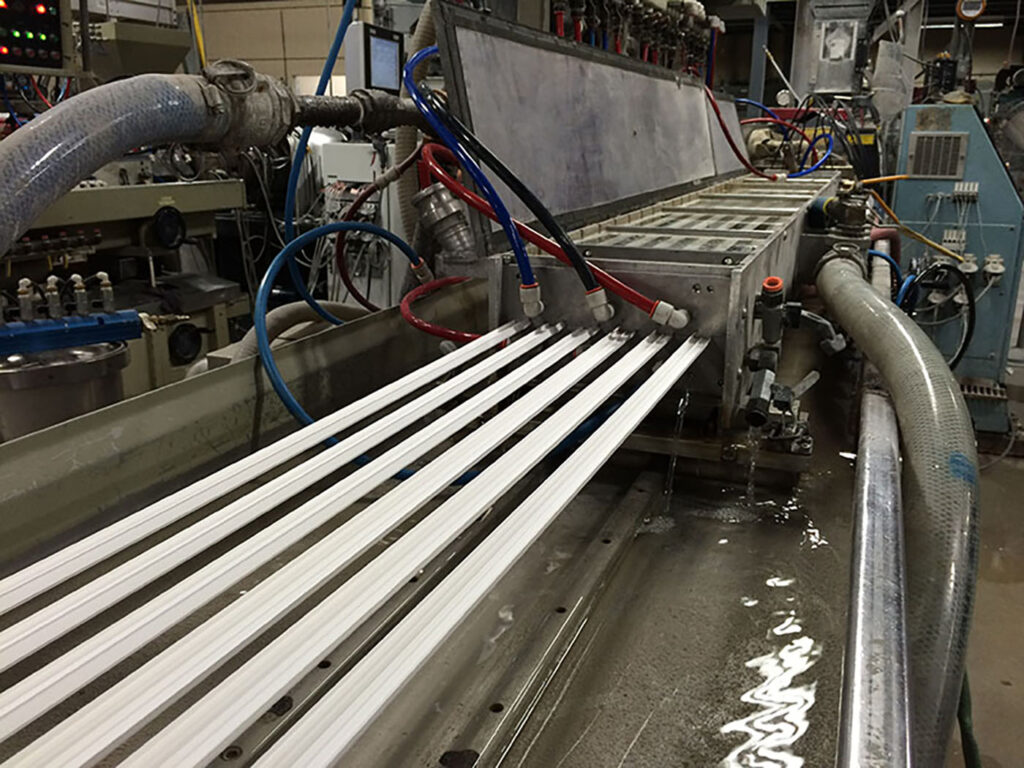

Inside the barrel, the material encounters heat and pressure, melting into a malleable state. This is where the magic happens: A rotating screw, akin to a giant, turning corkscrew, propels the now-fluid plastic towards the die – the mold that dictates the final shape of the product. Whether it’s a pipe, a frame, or a custom profile, the die is the gatekeeper to the plastic’s new form.

Emerging from the die, the plastic still holds the heat of transformation. It’s here that Adept Corporation’s precision engineering shines – our cooling systems solidify the plastic while maintaining the integrity of its new shape. The result? A continuous, uniform product ready for cutting, assembly, and life in the real world.

Adept Corporation: A Legacy of Innovation in Plastic Extrusion

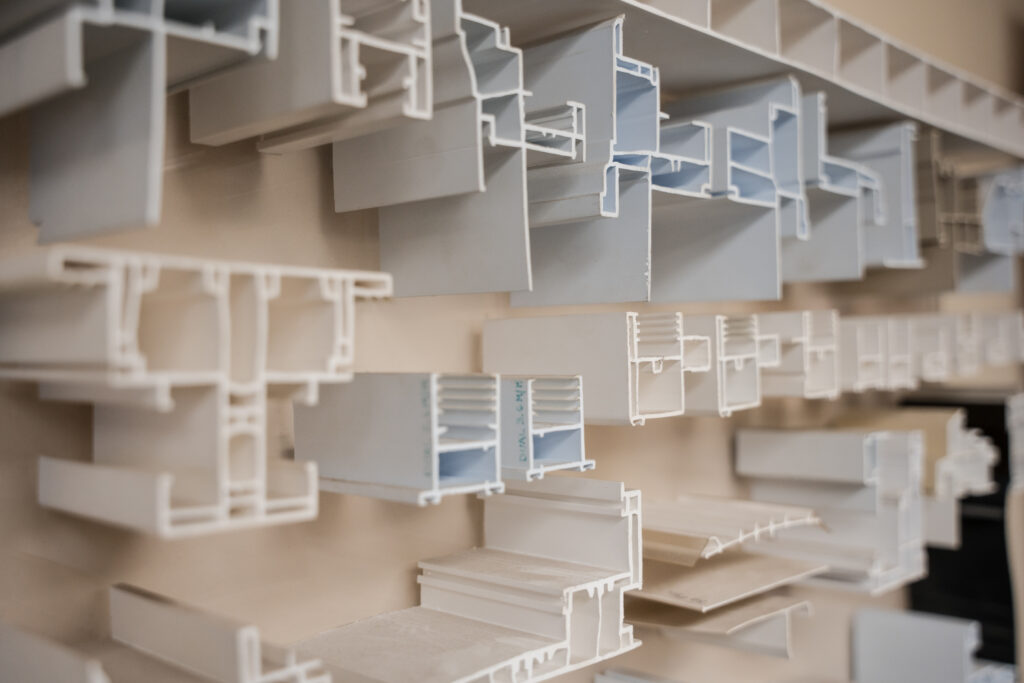

Since our transition into plastic extruded products in the late 20th century, Adept Corporation has embraced plastic extrusion with open arms and innovative minds. Our facility, equipped with state-of-the-art extrusion lines, has produced millions of feet of extrusion, serving the diverse needs of the building industry and beyond.

Our expertise is not just in executing flawless extrusion but also in understanding and utilizing a variety of materials, from PVC to ABS and beyond. This versatility allows us to cater to unique client needs, producing everything from rigid profiles for construction to flexible tubing for various applications.

Beyond the Profile: Adept’s Comprehensive Capabilities

But our commitment doesn’t end at extrusion. Adept Corporation is a full-service provider, offering related services such as Wire EDM Machining, CNC Machining, and Extrusion Polishing. Our approach is holistic: we don’t just create products; we craft solutions, ensuring every piece that leaves our facility meets our rigorous standards and our clients’ exacting demands.

Why Choose Adept Corporation for Your Plastic Extrusion Needs?

Choosing Adept Corporation means partnering with a company that has over five decades of experience, a deep commitment to quality, and a forward-looking approach to technology and service. We are not just manufacturers; we are innovators, problem-solvers, and, most importantly, your partners in building the future.

In the realm of plastic extrusion, Adept Corporation stands out. Our journey from a humble beginning to a leader in the manufacturing industry is a testament to our dedication, expertise, and the trust our clients place in us. Let’s shape the future together, one extrusion at a time.